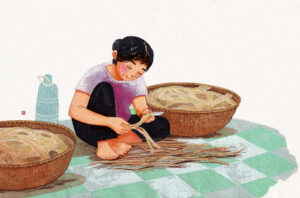

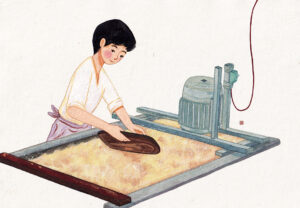

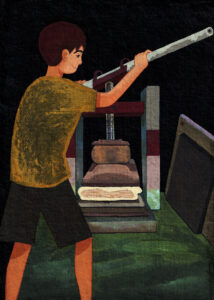

Ms. Ngo Thu Huyen (born in 1991) is a Do paper maker in Dong Cao village, Bac Ninh. Do paper - a delicate item, associated with the memories of many Vietnamese people and conveying the hearts of those who make it. To make Do paper, it is not only the effort of a Do carpenter (the person who coats the paper), but also the result of a "teamwork" process. Each different stage has the support of a family member, and other people in the village are hired to help with specialized tasks that require a lot of experience.

After graduating from university, Ms. Ngo Thu Huyen stayed in the city and started her office life. But the 8-hour rotation job did not bring her joy. She missed her grandfather's paper factory (Ngo Duc Do Paper) in the village, missed the drying yard with its fragrant scent on sunny days. When witnessing the entire Dong Cao village switching to industrial paper production following market trends, Ms. Huyen decided to leave the city and return to her hometown to learn how to make Do paper because she did not want to see the disappearance of the profession that her grandparents had devoted their whole lives to.

Ms. Huyen's sharing on Dep magazine, article "Ngo Duc Do Paper - Human life on a square of Do paper":

“I grew up making paper. My grandparents were both Do paper makers and introduced me to the craft very early. Every afternoon after school, I would sit in the corner of the yard, playing with the paper-making tools that my grandfather had prepared for me: a small mold that fit in my little hand, a basin of water, and some paper pulp. That was all it took for me to play all afternoon. When I was a little older, I would help my grandparents dry, strip, and fold the paper… From these tasks, I gradually developed a natural affection and connection with Do paper.

In 2015, while cleaning out a cupboard for my grandfather, I saw many ancient paper samples that were preserved. I suddenly became worried. My parents did not make Do paper, and there were not many households in the village that made it anymore, so my grandfather might be the last person to make these paper samples. I wanted to return to the village to continue that work. At first, my grandparents and parents objected because they understood very well the hardships of this profession. Do paper is not widely used now, so it is difficult to bring in a stable income. I also worried a lot, but the fear of Do paper disappearing kept coming back, making me determined to return in 2017."

“Ngo is the family name, and Duc is the middle name in my family branch. Our ancestors built a foundation of craftsmanship, including knowledge and experience from the working process. The younger generation like me is fortunate to inherit that foundation and have the opportunity to continue and develop it. So I chose the name Ngo Duc, with the previous generation, with myself, and with the expectation of a long-term continuation.”

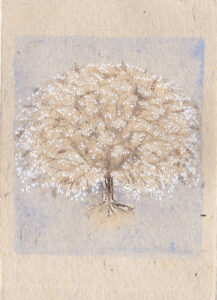

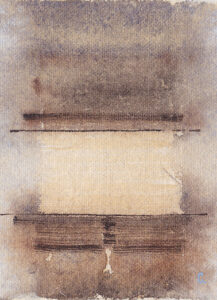

“My grandfather taught me the knowledge and practice of paper making, from the first steps to the final product. The ancients made paper for painting and calligraphy, and I first made Do paper for Calligraphy and watercolor painting. If when I was young I stood watching him work, running around helping with chores, now I do it myself, he will be there to give advice and help. That image reminds me of the peaceful and beautiful childhood I spent with my grandparents. The first piece of paper was made, I held it in my hand, smelled the scent, looked closely at the paper grain and realized: The fragile paper was formed after many months thanks to the skillful hands of the craftsman, it is tough, durable, thin but does not smudge ink when writing and drawing. If preserved properly, the paper will remain intact after hundreds of years as new.”

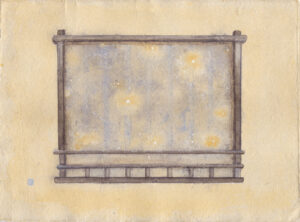

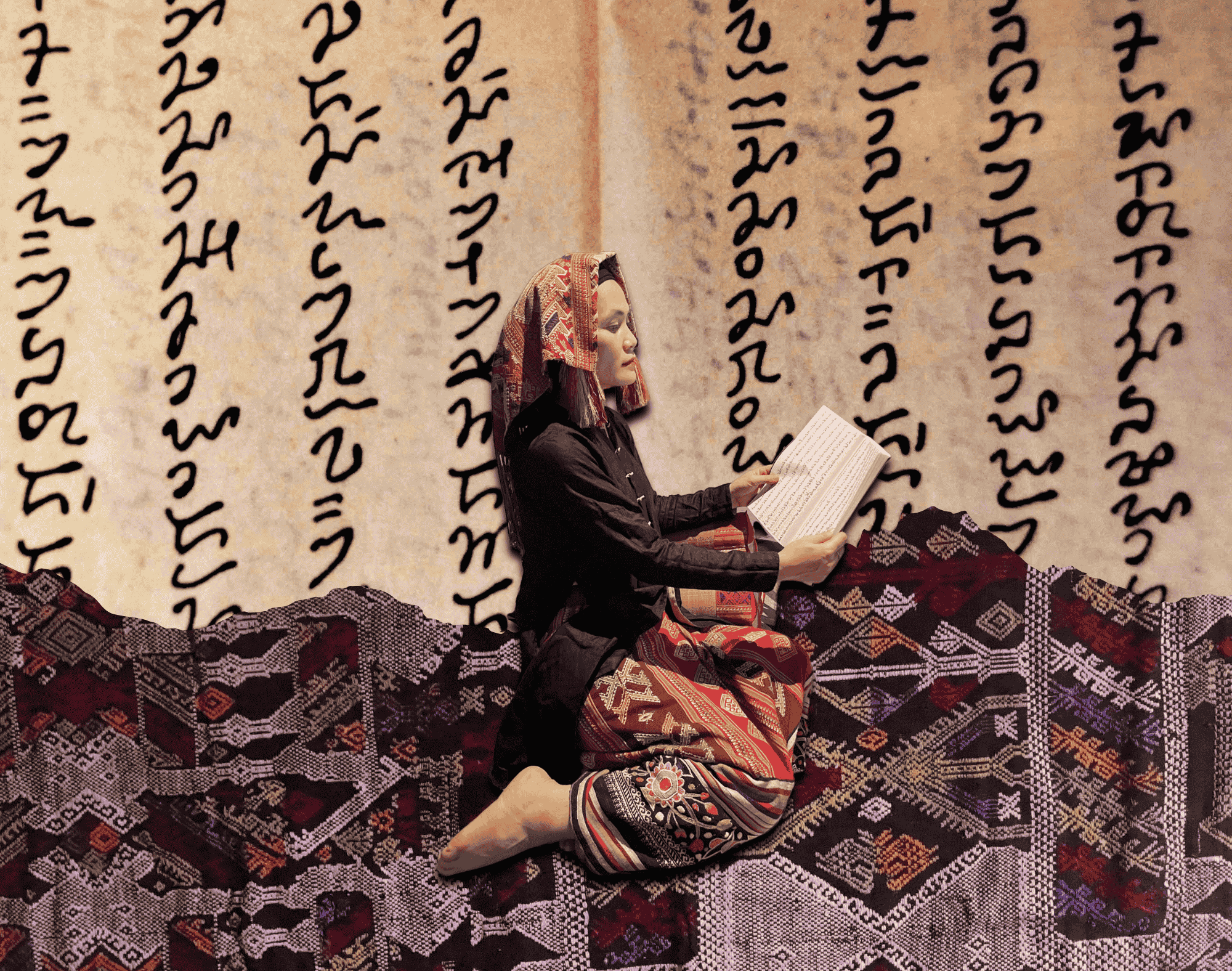

“When the paper leaves the workshop, it begins a new life. I don’t know how customers will use it. The paper will be drawn, written, printed, made into notebooks, decorated, used as a backdrop for photography… depending on each person’s creativity, I really look forward to seeing those works. Dó paper has a simple appearance, it is not eye-catching at first sight, but if you pay attention and learn, you will realize its precious things: the golden brown color sparkling under the light, the thin silk fibers that last over time… Looking at Dó paper, I can also see the lives of the people in my hometown. When they were young, they practiced writing and drawing on Dó paper. When they grew up, they used Dó paper to write letters and record their family tree. At the end of their lives, they brought Dó paper with them on their new journey. The old people in the village sometimes asked me for a few pieces of Dó paper to put in their coffins when they left this world.”

Introductory information and notes were contributed by the Do paper maker: Ngo Thu Huyen. Watercolor illustrations on Ngo Duc Do paper were made by artist: Nguyen Cam Anh.

All information posted in the Connecting Heritage Digital Collection is contributed by the community and is for reference only. The Program is not responsible for any differences from the information stated in the Digital Collection and disclaims any liability arising from the use of information from this Collection. Refer to the Community Rules for more information.